The GP type disc vacuum filter achieves the filtration effect by extracting air and carrying impurities through it. Therefore, in the index of the GP type disc vacuum filter, one item is the amount of air extraction rate. The higher the air extraction rate, the greater the filtration volume. A low pumping rate leads to a correspondingly small filtration volume. For large vacuum filters, the filtrate tubes inside are also thick and have a larger tube surface.

Technical features of GP type disc vacuum filter

1. The stirring adopts multiple combined seals such as VD type sealing rings, water seals, skeleton oil seals and combined packing, ensuring no slurry leakage during long-term use.

2. Dry oil pumps are adopted for centralized oil injection lubrication to ensure the normal operation of the equipment.

3. The filter cloth is automatically cleaned to maintain its good air permeability and excellent dehydration effect.

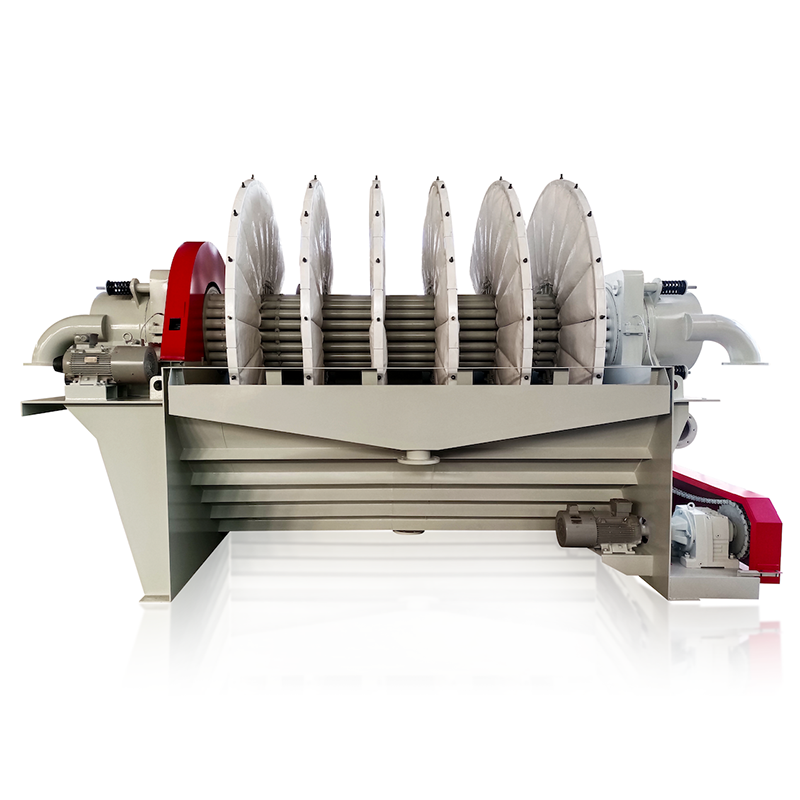

4. The filter fan is molded from ultra-high strength polypropylene, featuring high strength, resistance to deformation, and a service life that is 2 to 3 times longer. The opening rate of the filter fan is as high as 30%, which ensures that the filtration effect will not be affected by clogging and is conducive to further increasing production and reducing the moisture content of the filter cake.

5. Each disc of the filter fan is composed of 20 sector plates with an 18° Angle. Compared with each disc having 12 sector plates, each sector plate can suck materials 12° earlier in the suction zone and extend the dehydration and drying by 12° in the drying zone. This means higher output and lower moisture content.

6. The friction plates and control panels are cast from high anti-friction boron-phosphorus cast iron, ensuring a long service life.

7. The cross-section of the filtrate pipe is large, and the volume of the distribution head cavity is also large, which is conducive to improving the pumping rate and filtrate discharge.

8. For materials with high viscosity, a combined unloading method of "scraper + reverse blowing" can be adopted, which results in a high rate of filter cake shedding.

9. The structure of the filtrate pipe has been optimized, completely eliminating the air leakage caused by the aging of the rubber at the original flange connection.

10. It adopts gear transmission and variable frequency speed regulation, with a wide speed regulation range and reliable operation.

The GP series disc vacuum filter for flotation clean coal produced by our company fully draws on the technical advantages of similar foreign products and continuously optimizes the overall performance of the machine. Practical application has proved that the main technical and performance indicators of this product have reached the advanced level of similar domestic products. In addition, it has the advantages of low moisture content of the filter cake, high filtration coefficient, small floor space, and simple operation and maintenance.

The GP type disc vacuum filter has become a high-level project at both the national and provincial levels. There are also relevant recognition certificates in terms of technical patents. These recognition certificates can help enterprises choosing the GP type disc vacuum filter to keep their eyes open. Moreover, our technology has already broken away from foreign technical guidance and is fully capable of independent technology.