location

West Chuangxin Road, Sunshine Industrial Park, Donggang Town, Xishan District, Wuxi City, China

West Chuangxin Road, Sunshine Industrial Park, Donggang Town, Xishan District, Wuxi City, China

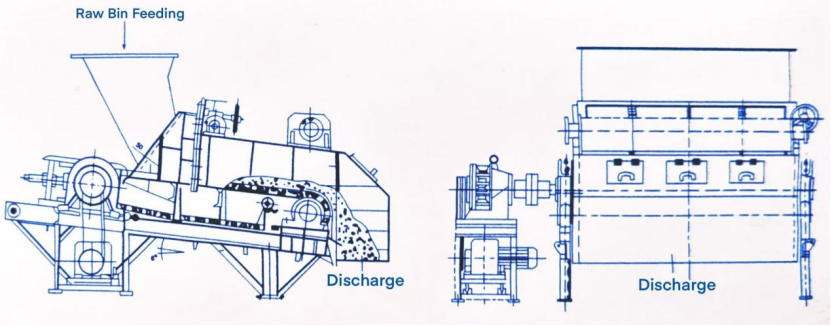

The LG Type Chain Feeder is a continuous and uniform feeding device engineered for beneficiation and separation systems that process medium-sized bulk materials. It is extensively utilized in coal preparation, mineral processing, metallurgy, cement production, and the chemical industry.

This feeder is suitable for mixed loose materials with particle sizes ranging from 0 to 100 mm, especially in applications where material size distribution is inconsistent and moisture content fluctuates.

· Feeding systems for jigging, separation, and classification equipment

· Pre-treatment and material distribution sections

· Continuous feeding applications require a stable and uniform material bed

As a front-end feeding device, the LG Type Chain Feeder enhances feed consistency and serves as a critical component for maintaining stable operation and optimizing separation efficiency in downstream equipment.

The LG Type Chain Feeder utilizes a chain-driven feeding structure. It distributes material uniformly across the entire working width of downstream equipment, thereby continuously providing a stable and even material bed.

Key features include:

· Formation of a uniform material layer with consistent thickness

· Elimination of localized overfeeding, starvation, or material segregation

· Improved operational stability of downstream separation and beneficiation equipment

The feeder enables adjustment of the feed rate to meet specific process requirements and accommodate varying equipment operating conditions:

· Continuously adjustable feed rate via chain speed control

· Manual or automated regulation available

· Maintains bed stability and improves separation accuracy and recovery efficiency

Maintaining a stable feed condition enhances product quality, minimizes material misplacement, and supports consistent process control.

The following parameters are customizable to align with specific process requirements:

· Suitable material size: 0–100 mm

· Feeding capacity: Designed to match downstream equipment throughput

· Feeding width: Customized to the equipment working width

· Feeding mode: Continuous, uniform chain feeding

· Control method: Variable frequency drive (VFD) or mechanical speed regulation (optional)

· Drive system: Electric motor + gearbox + chain transmission

· Operating mode: Continuous duty

· Installation position: Upstream of separation or processing equipment

· Provides stable and uniform material feeding

· Enhances process consistency and separation performance

· Adapts effectively to variable material conditions

· Features a reliable structure suitable for continuous industrial operation

· Facilitates integration into existing process lines

Feed uniformity in beneficiation and separation systems directly influences process stability and overall performance. The LG Type Chain Feeder is specifically designed to address this essential requirement.

· Optimized for uniform bed formation, supporting stable downstream operation

· Continuous and controllable feeding, enabling precise process control

· Strong adaptability to varying material conditions

· High compatibility with existing equipment and process layouts

· Proven chain-driven structure for long-term reliable operation

Selecting the LG Type Chain Feeder ensures controlled feeding, stable processing, and consistent system performance across diverse industrial applications.