GW-T Series External-Feed Vacuum Drum Filter for Slurry Dewatering

External-feed vacuum drum filters for continuous solid–liquid separation. Ideal for mineral concentrates, coal slurry, chemical slurries, and tailings dewatering.

Tongzhiren GW-T vacuum drum filter set waiting to be shipped out

Filtration equipment is widely used in process industries for continuous solid–liquid separation. Such equipment utilizes a pressure differential across a porous medium, for instance, filter cloths or filter plates. Under a mechanically formed ideal vacuum state, the liquid component passes through the selected filter medium while the solids are retained in the form of a stable, relatively low-moisture filter cake.

location

West Chuangxin Road, Sunshine Industrial Park, Donggang Town, Xishan District, Wuxi City, China

Working Principle of Vacuum Filtration Systems

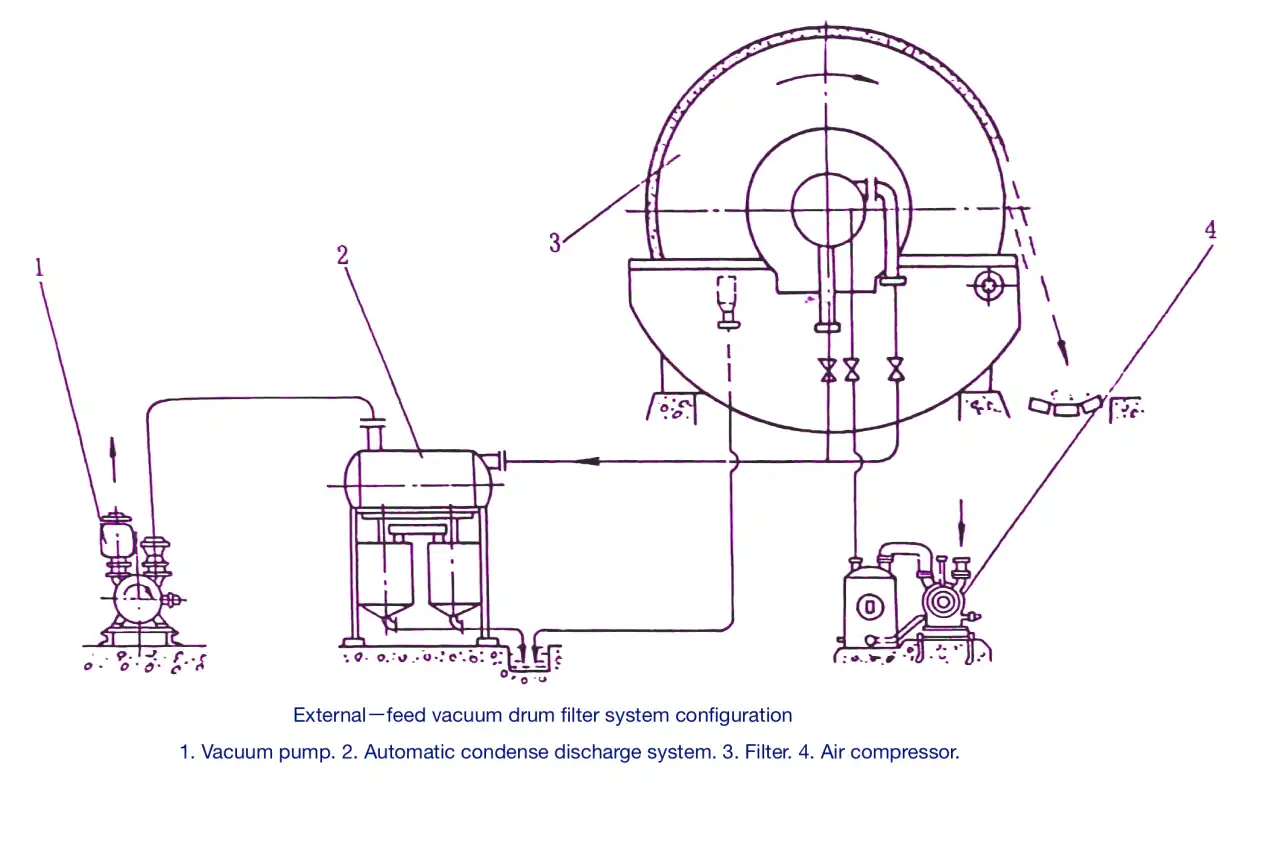

The core operating principle of a vacuum drum filter is pressure-differential filtration.

A vacuum pump creates negative pressure inside the filtration chambers of the rotating drum. As the drum partially immerses into the slurry tank, the liquid phase is drawn through the industrial filter cloth and collected as filtrate. Solid particles remain on the cloth surface, gradually forming a uniform filter cake.

As the drum rotates:

- Slurry filtration occurs in the immersion zone

- Cake dewatering takes place in the drying zone

- Cake discharge is achieved via compressed air, scraper blade, or roller

- Filter cloth washing prepares the surface for the next cycle

This coordinated process enables continuous and stable solid–liquid separation.

What Is a Vacuum Drum Filter ?

A major category within the filtration equipment is vacuum drum filters. A vacuum drum filter is a type of continuous vacuum filtration equipment used to separate solids from liquids in slurry form. The system applies negative pressure across a filter medium, allowing liquid to pass through while solids are retained on the filter cloth surface, forming a filter cake. Vacuum drum filters are commonly used where large throughput, continuous operation, and controlled cake moisture are required.

Vacuum drum filters are currently widely used in metallurgical processing, coal preparation, chemical and inorganic materials processing, fertilizer and phosphate production, pigment and mineral powder manufacturing, industrial wastewater and sludge dewatering, and tailings management.

Within the vacuum drum filter category, several classifications exist: external-feed, internal-feed, belt-discharge, and permanent-magnet external-feed. These models are divided by the characteristics of their processed materials and process requirements.

External-feed vacuum drum filters are widely used in industrial slurry dewatering and solid–liquid separation processes. Operating under a controlled vacuum pressure differential, this filtration equipment delivers continuous operation, stable cake formation, and low residual moisture, making it suitable for demanding process industries.

Designed for mineral processing, coal preparation, chemical slurry filtration, and tailings dewatering, external-feed vacuum drum filters provide reliable performance under harsh operating conditions while supporting water recovery, resource recycling, and environmental compliance.

Our company specializes in the customization and manufacturing of external-feed vacuum drum filters (GW-T series), designed for reliable, continuous operation in mineral concentrate dewatering, coal slurry processing, chemical slurries, and industrial liquid residue treatment. These solutions support resource recycling by enabling sites to reuse separated water or repurpose the solid filter cake. Additionally, this filtration process addresses environmental sustainability by managing hazardous slurry, reducing environmental risks, and ensuring compliance with pollution control protocols and environmental protection laws.

Types of Vacuum Drum Filters and Selection Guidelines

Vacuum drum filters are classified according to material characteristics and process requirements:

1

Internal-Feed Vacuum Drum Filters

Best suited for coarse particles, higher-density slurries, and fast-settling materials, such as iron ore concentrates from magnetic separation and flotation circuits.

2

External-Feed Vacuum Drum Filters

Ideal for fine-grained, slow-settling, or viscous slurries that require low final cake moisture, commonly found in non-ferrous metal and non-metallic mineral processing.

3

Belt-Discharge Vacuum Drum Filters

Applied when gentle cake handling and controlled discharge are required.

4

Permanent-Magnet Vacuum Drum Filters

Used primarily for coarse magnetite concentrates, where magnetic assistance improves cake stability and filtration efficiency.

Proper selection depends on particle size distribution, slurry concentration, filtration rate, cake moisture target, and discharge behavior.

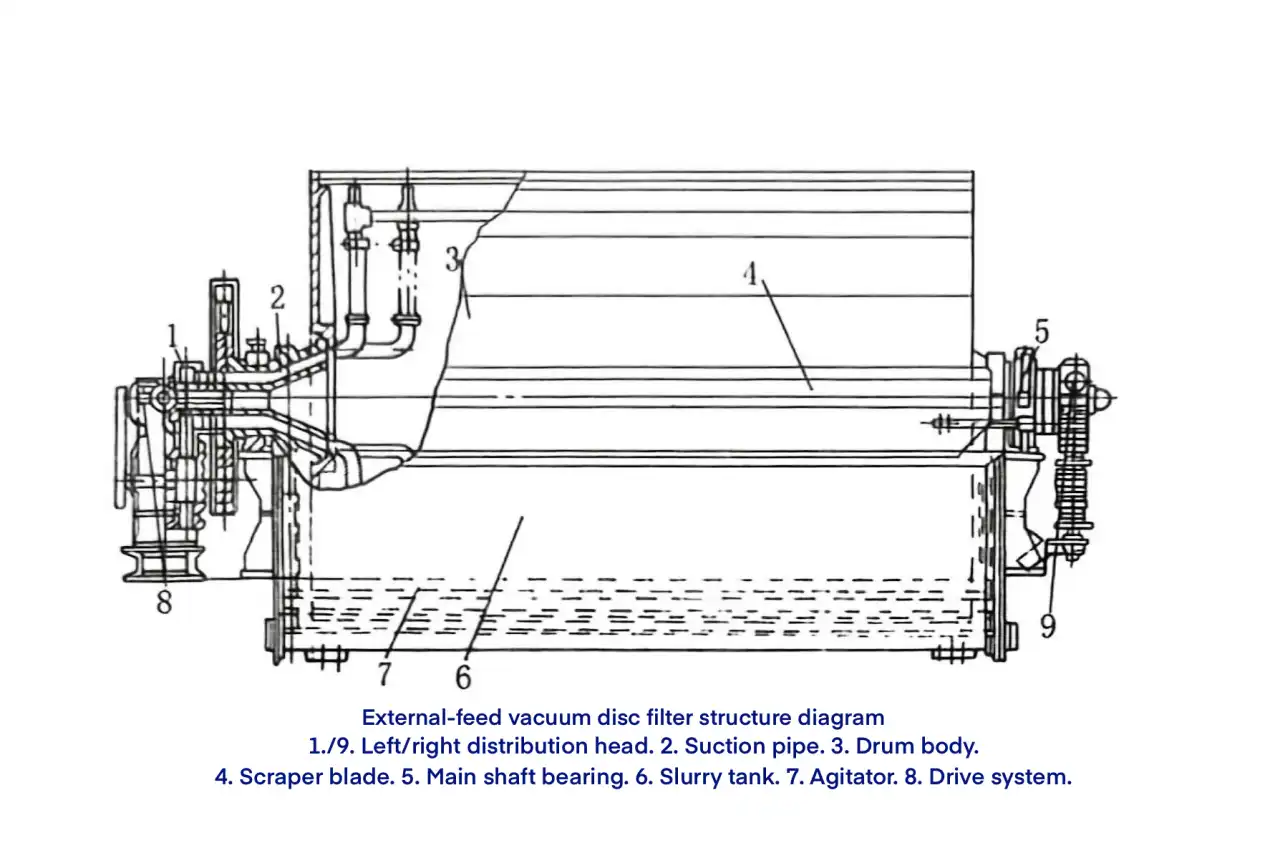

GW-T Series External-Feed Vacuum Drum Filter Design

The GW-T series external-feed vacuum drum filter is engineered for reliable, long-term continuous operation in demanding industrial environments.

Structural Features

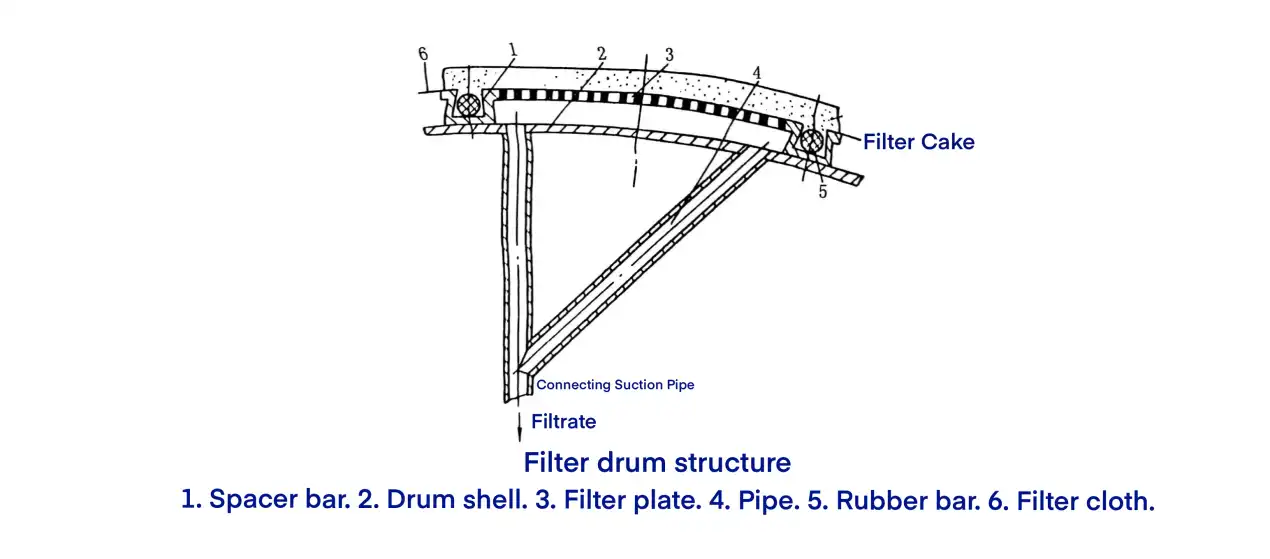

- Drum surface covered with industrial-grade filter cloth

- Filter cloth secured using partition bars and sealing materials to prevent vacuum leakage

- Wire-winding fixation system ensures stable cloth positioning

- Heavy-duty rotary distribution valve controls each filtration chamber

- Stationary distribution head connects to vacuum and compressed air systems

- Variable-speed drive system adapts to different slurry characteristics

In an external-feed vacuum drum filter, the drum’s outer surface is covered with filter cloth. To ensure effective sealing between filtration chambers, the cloth is secured in the rope grooves of partition bars using sealing strips such as rubber cords, hemp rope, or palm fiber. The cloth is fixed to the drum shell by a wire-winding mechanism, which wraps steel wire around the drum axially at intervals of about 50–80 mm to ensure stable positioning and long-term operation.

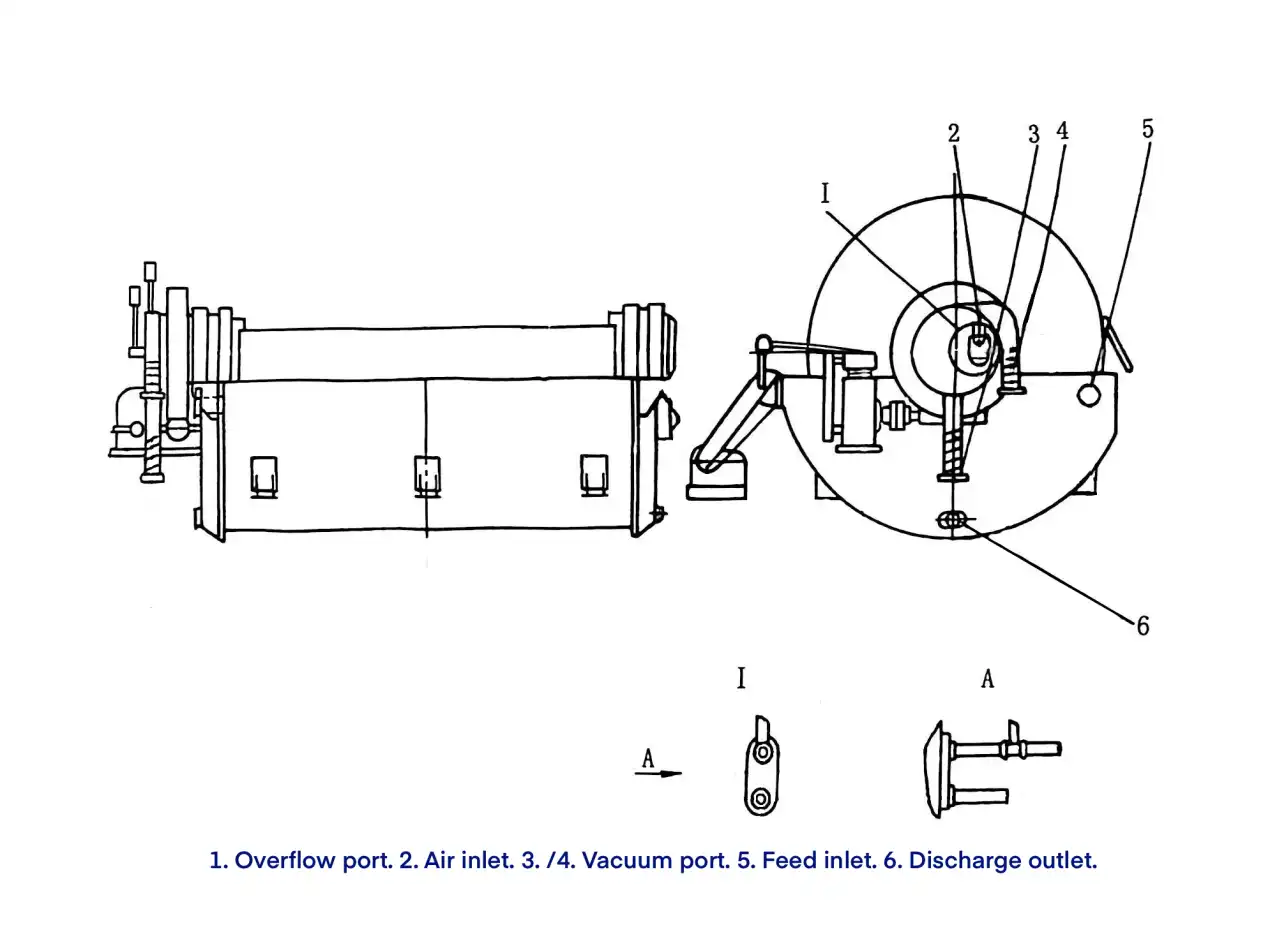

At one end of the drum, a rotary distribution valve (rotary valve head) is installed. The valve contains individual ports corresponding to each filtration chamber,At one end of the drum, a rotary distribution valve (rotary valve head) is installed. The valve contains individual ports corresponding to each filtration chamber, with each port connected via piping to its respective chamber.

The drive system rotates the drum at selectable speeds, allowing adaptation to various slurry characteristics and process requirements.

The distribution head is a key component that remains stationary during operation. One face maintains sliding contact with the rotary valve, while the other connects to the vacuum pump and air blower system.

Controlled valve timing allows the distribution head to sequentially manage each filtration chamber, enabling filtration, cake dewatering, discharge, and filter cloth washing in a continuous cycle.

The slurry tank is located beneath the drum and serves to hold the feed slurry. A reciprocating agitator in the tank keeps solid particles in suspension, ensuring uniform filtration. During operation, approximately one-third of the drum surface is immersed in the slurry. The drum is supported on the slurry tank by main bearings mounted on the central shaft.

Dewatering Performance and Cake Moisture Control

External-feed vacuum drum filters are designed to achieve low residual cake moisture while maintaining high throughput.

For fine or viscous slurries, optional dewatering enhancements may include:

- Compression rollers

- Pressure belts

- Cake knockers or smoothing blades

These auxiliary devices improve cake density, dewatering efficiency, and discharge reliability, particularly in applications with strict moisture requirements.

In addition to conventional bottom-feed configurations, top-feed and side-feed arrangements are available, particularly for materials with coarser particle sizes and faster settling characteristics.

For cake discharge, in addition to the standard compressed-air blow-off method, alternatives such as discharge rollers or string discharge systems can be used, depending on the material behavior.

External-feed vacuum drum filters are widely used in mineral processing plants to dewater flotation concentrates, including non-ferrous metals such as copper, zinc, aluminum, and nickel, non-metallic minerals such as sulfur, phosphorus, talc, and fluorite, and flotation clean coal.

Industrial Applications of External-Feed Vacuum Drum Filters

External-feed vacuum drum filters are widely applied in:

- Mineral processing plants

- Flotation concentrate dewatering

- Coal slurry and clean coal filtration

- Non-ferrous metals (copper, zinc, aluminum, nickel)

- Non-metallic minerals (sulfur, phosphorus, talc, fluorite)

- Chemical slurry processing

- Industrial wastewater and sludge dewatering

- Tailings management and water recovery systems

Their ability to handle fine particles and poor settling characteristics makes them a preferred solution across multiple process industries.