Our TPT ceramic vacuum disc filter is a high-efficiency, energy-saving filtration system that uses electromechanical micro-porous ceramics and ultrasonic technology. It separates solids from liquids through vacuum suction and capillary action, and is used in the chemical industry, mining, metallurgy, and environmental conservation.

The working principle, structure, production results, and advantages of the company's ceramic disc vacuum filter are introduced below.

A high-tech new product that integrates multiple functions:

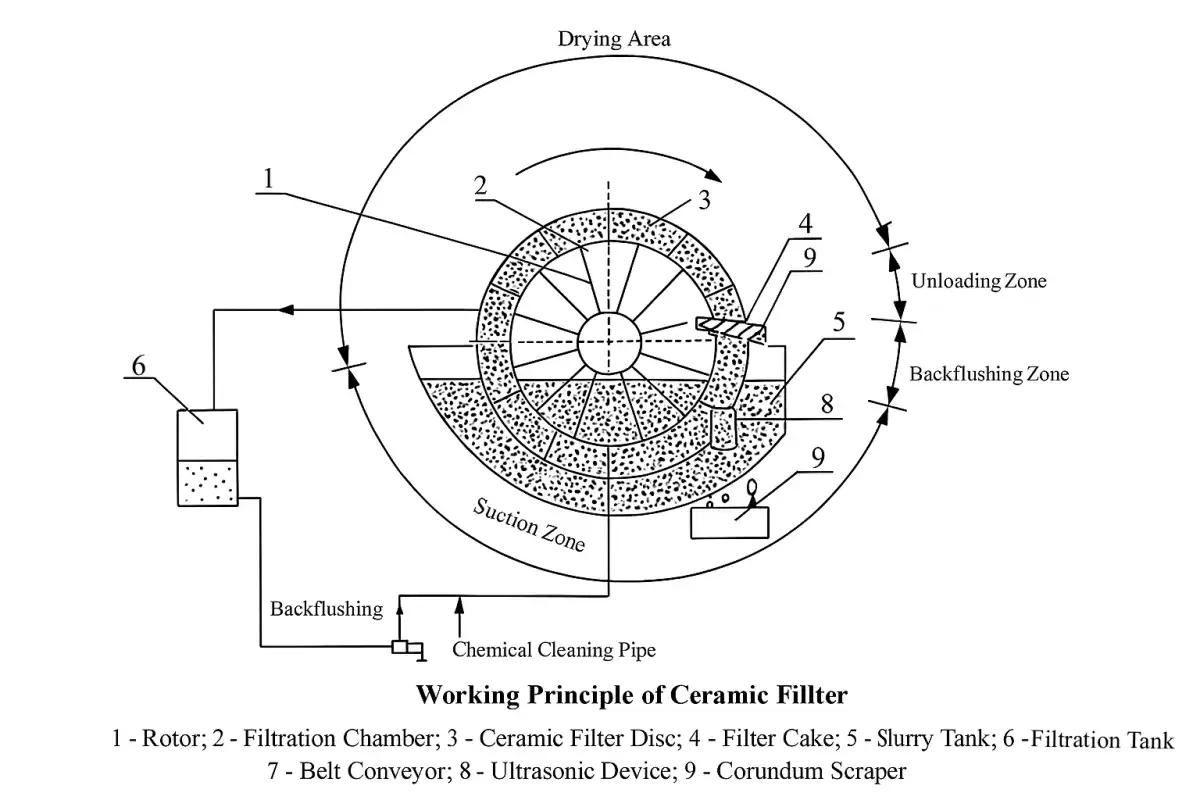

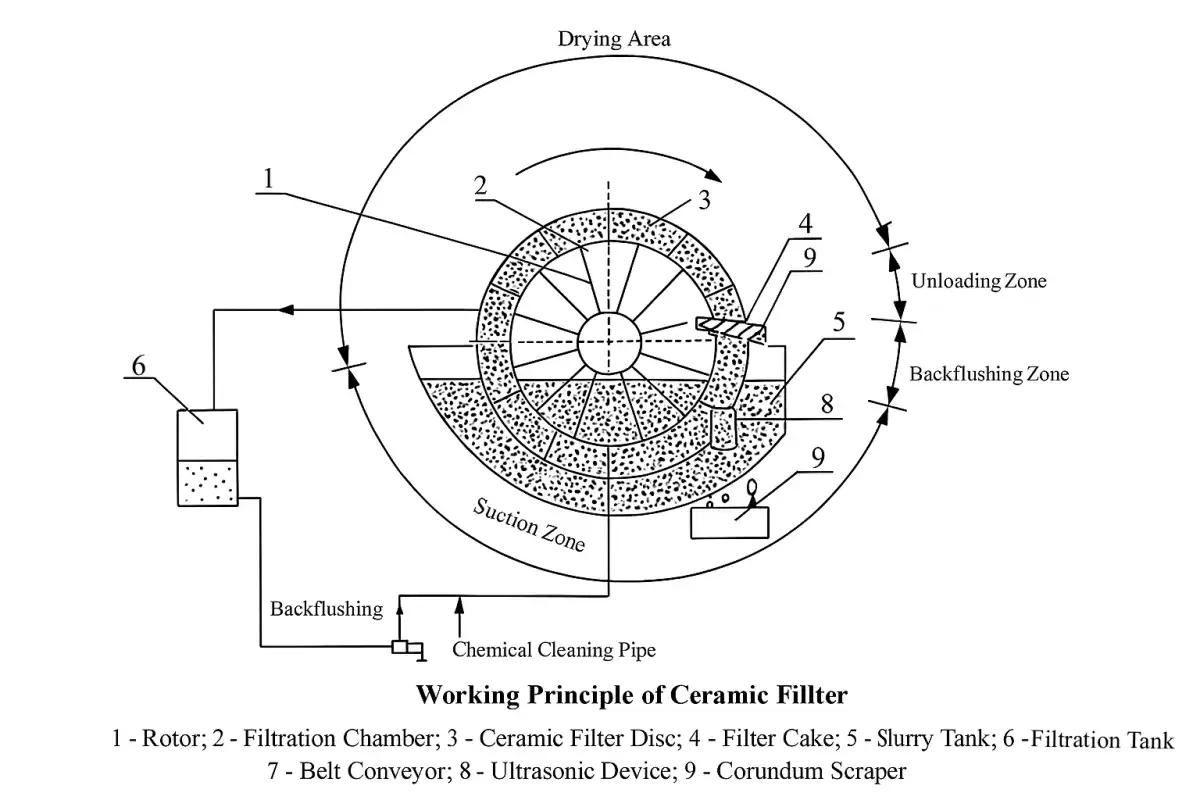

1. Working Principle of Ceramic Disc Vacuum Filter: This filter integrates high technologies such as electromechanical systems, microporous filter plates, automated control, and ultrasonic cleaning.

(1) Capillary effect and its application in microporous filter plates. Traditional vacuum filters not only have high vacuum pump power, but also, due to the large pore size of the filter cloth and its tendency to leak water, it is difficult to maintain an extremely high vacuum during the dehydration process. The outstanding feature of ceramic filters is that they can achieve an extremely high vacuum (-0.09 to -0.098 MPa) with very low energy consumption. The main reason for this low energy consumption and high vacuum is the application of the capillary effect principle in microporous filter plates. Through repeated research and experiments, it was found that when the pore size of the filter medium is appropriate, the surface tension within the micropores exceeds the vacuum pressure. At this time, water inside the micropores will not escape, thereby achieving the purpose of the microporous filter plate: allowing only water to pass while preventing air from passing. Therefore, while ensuring an extremely high vacuum inside the filter plate, energy consumption can be greatly reduced. Under normal circumstances, ceramic filters only require a very small vacuum pump (power 0.8~3kW) to meet the high-vacuum requirements in the production process.

(2) Working principle of ceramic filters. The design principle of ceramic filters is to achieve high vacuum, low energy consumption, full automation, high efficiency, and high separation accuracy.