In early 2014, the company partnered with leading design institutes to develop a new generation of gypsum slurry dewatering equipment, the high-efficiency disc filter cloth dewatering machine (Patent No.: ZL.2016 1029933.X). Drawing on advanced domestic and international technologies, this product features independent intellectual property rights and innovative technology. It was commissioned at the Changxing Power Plant of Huaneng Power International Corporation Limited in May 2015, marking the industry's first successful application of this technology. Since then, over 80 power plants and more than 150 units have adopted the system. We have established partnerships with major power groups, including Huaneng, Huadian, Guohua, Guodian, China Power Investment Corporation, Datang, Zhejiang Energy, Guangdong Electric, and Shaanxi Energy.

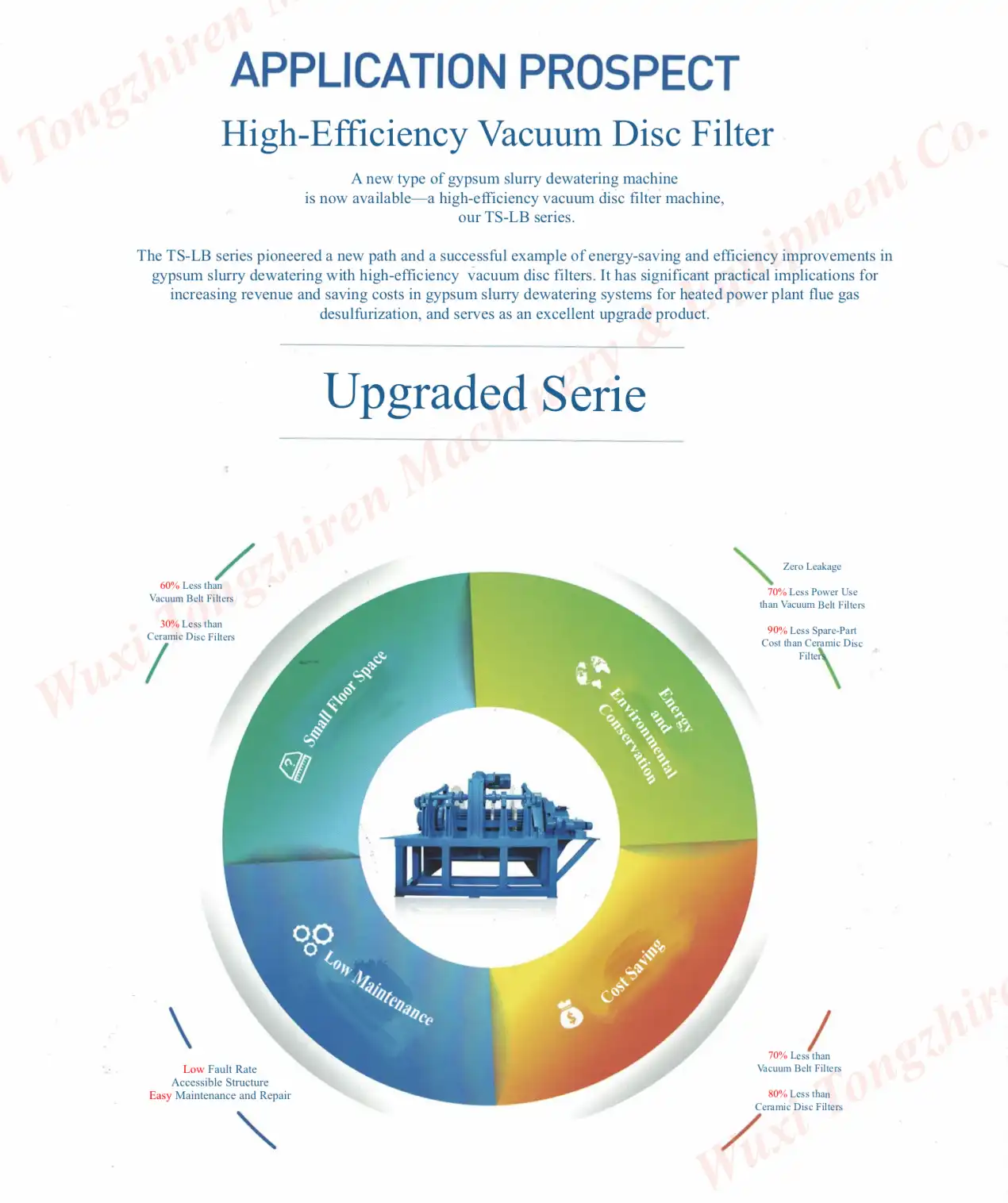

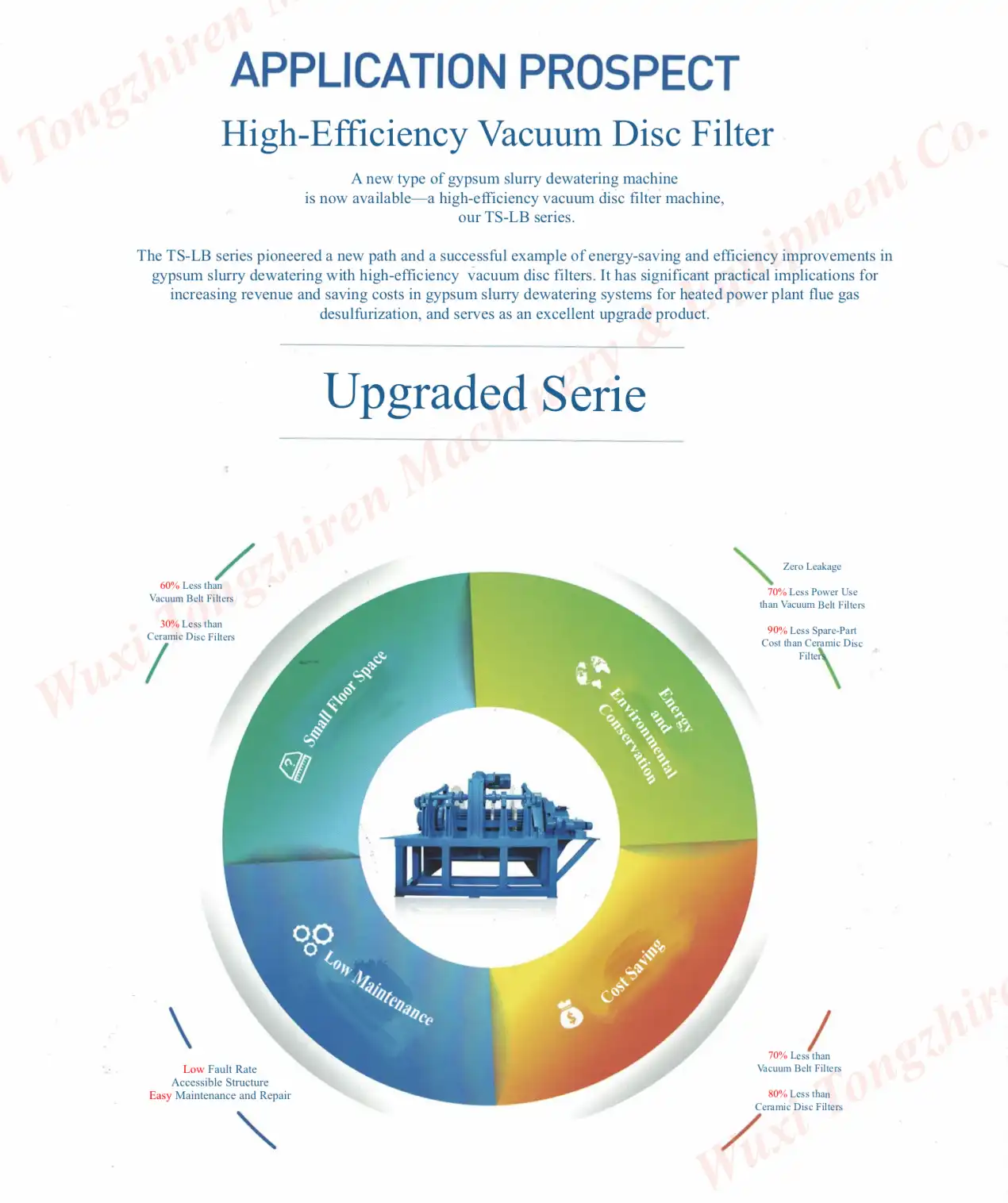

The main advantages of the high-efficiency disc filter cloth dehydrator over the traditional vacuum belt dehydrator are as follows:

Low system energy consumption

Compared to vacuum belt dewatering machines of similar capacity, the disc filter cloth dewatering machine reduces electricity consumption by over 75%. For example, at Huadian Zhangqiu Power Plant (gypsum output: 50 tons per hour), a belt dewatering machine consumes nearly 400KW, while the disc filter cloth dewatering machine uses only 88KW, resulting in more than 77% electricity savings. This demonstrates a clear energy-saving advantage.

The disc filter cloth dewatering machine also reduces water consumption by over 80% compared to vacuum belt dewatering machines. While belt machines require continuous flushing of the filter cloth, the disc filter cloth dewatering machine only needs a single system cleaning before shutdown, which takes about 10 minutes and uses approximately 6 tons of water. The water-saving benefits are significant.

Small floor space

The disc filter cloth dewatering machine occupies only about 20% of the space required by a vacuum belt dewatering machine. This allows for a more efficient and organized equipment layout, especially in new power plants, and significantly reduces civil construction costs.

Strong adaptability to materials

The disc filter cloth dewatering machine uses a micro-porous diaphragm formed by the filter cloth and the filter cake, providing strong adaptability to varying materials. It performs reliably with coal-containing wastewater, oil-containing and high-ash slurries, and wastewater sludge, maintaining stable moisture content and output. Some power plants also mix small amounts of desulfurization wastewater sludge into gypsum slurry for joint treatment.

Improve the working environment

Gypsum slurry temperatures exceed 60 degrees. Belt dewatering machines have large, open dewatering areas, which allow harmful hot steam to spread, causing equipment corrosion and posing health risks to staff. In contrast, the disc filter cloth dewatering machine has a compact dewatering area (about 12 square meters for a 50-ton-per-hour unit) and is equipped with a steam barrier device. Its high vacuum and rapid filtrate flow prevent the diffusion of harmful gases, significantly improving the working environment.

High vacuum degree utilization rate

The high-efficiency disc filter cloth dewatering machine uses vacuum tubes to fully seal each filter fan, which significantly reduces unnecessary power consumption. It achieves a vacuum range of -0.06 to 0.075 MPa, compared to -0.03 to 0.04 MPa for vacuum belt dewatering machines. This higher vacuum utilization ensures better control of filter cake moisture content.

Low operating cost

The primary consumable for the disc filter cloth dewatering machine is the filter cloth. Annual replacement costs are about 60% of those for belt conveyors. Belt conveyors also require numerous bearings and idlers, increasing maintenance needs. Overall, annual maintenance costs for the disc filter cloth dewatering machine are approximately 30-50% lower than those for belt dewatering machines.

Once operational, the disc filter cloth dewatering system significantly reduces noise, dust, sewage, and harmful steam in the dewatering workshop. Its simple structure contains no large or high-speed rotating parts. Core and flow-through components are made of 2205 material, offering strong anti-corrosion properties. The equipment also reduces installation area and energy consumption, resulting in substantial cost savings during construction and daily operation, and supporting more efficient future production management.