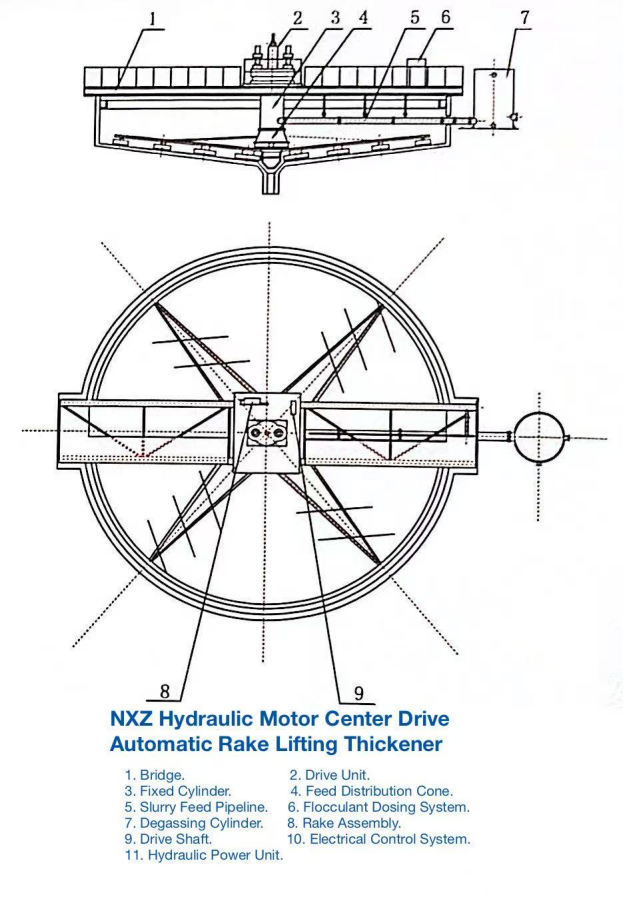

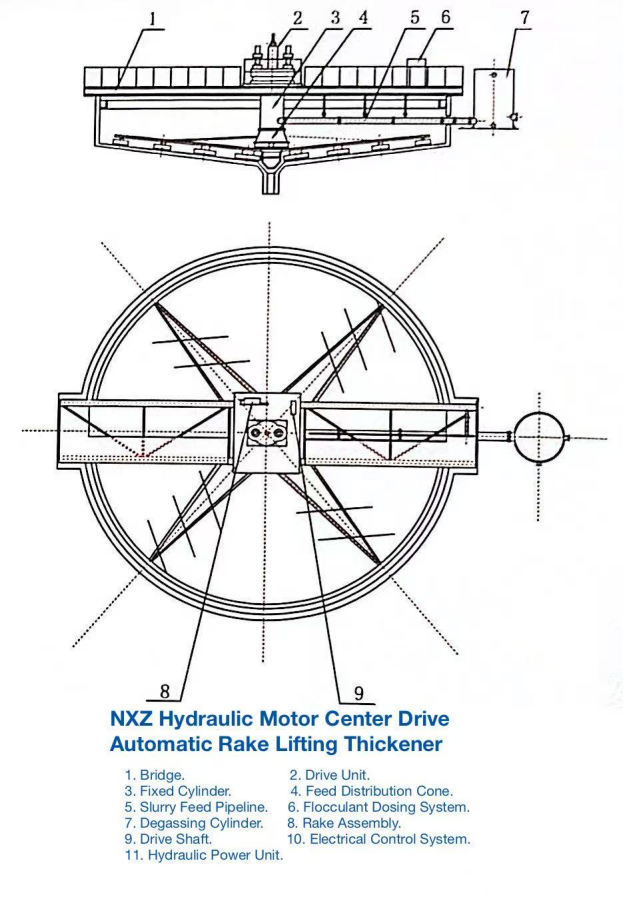

NXZ Series Hydraulic Motor Center Drive Automatic Rake Lifting Thickener for Solid–Liquid Separation and Slurry Concentration

1. Thickener Equipment Overview (Mining & Mineral Processing Applications)

A thickener is a critical large-scale process equipment widely used for solid–liquid separation and slurry concentration in mining, mineral processing, metallurgy, chemical processing, and environmental engineering. Its core function is to accelerate the settling of solid particles through gravity sedimentation combined with flocculation, while producing clarified overflow water suitable for reuse or controlled discharge.

In mineral processing plants and tailings treatment systems, thickeners are typically installed downstream of grinding, flotation, gravity separation, and classification circuits. They are used for the concentration of intermediate products, mineral concentrates, and tailings slurry, providing stable feed conditions for filtration, slurry transport, water recovery, and tailings disposal.

With increasingly fine ore particle sizes, higher plant throughput requirements, and stricter water-recycling standards, modern mining thickeners have evolved into heavy-duty, high-efficiency process units that integrate:

l Advanced flocculation technology

l Stable and reliable drive systems

l Intelligent control and protection

l Optimized tank hydraulics

These developments significantly improve thickening efficiency, operational stability, and water recovery performance.

2. Technical Design Concept of This High-Performance Thickener Series

NXZ series of high-efficiency mining thickeners is developed based on extensive domestic and international operating experience. The design philosophy focuses on:

l High reliability

l High processing capacity

l Low failure rate

l Low maintenance cost

Systematic improvements have been implemented in the drive system, feed distribution structure, flocculation and stirring mechanism, rake lifting protection, and control system, making this thickener suitable for continuous heavy-load operation.

Unlike conventional thickeners using rigid mechanical drives, this equipment adopts an advanced hydraulic flexible drive system, which significantly improves operational stability under variable load conditions and reduces mechanical stress. Combined with optimized tank structure, feedwell design, reagent dosing system, and slurry flow path, the thickener achieves faster settling rates, higher underflow concentration, and clearer overflow water.

This thickener series is especially suitable for:

l Fine-particle mineral slurries

l High-clay and high-mud content ores

l Tailings thickening and water recovery systems

l Applications requiring high overflow clarity

3. Key Technical Features and Innovations

3.1 Hydraulic Flexible Drive System

The adoption of a hydraulic flexible drive replaces traditional rigid drive structures, greatly enhancing equipment reliability and reducing mechanical shock during long-term continuous operation. This design effectively lowers equipment failure rate, downtime, and maintenance workload, making it ideal for large mining operations.

3.2 Advanced Stirring and Flocculation Technology

An optimized stirring–flocculation system ensures thorough mixing of flocculants and slurry, allowing fine suspended particles to rapidly agglomerate into large flocs. This significantly improves settling velocity, thickening efficiency, and underflow density.

3.3 Optimized Slurry Feeding System

The traditional vertical feed into the clarified zone is replaced with a submerged deep-feed distribution method, minimizing turbulence and improving internal hydraulic conditions. This design enhances fine particle settling and overall thickener performance.

3.4 Feedwell with Horizontal Grating Structure

The feedwell is equipped with horizontal grating elements, promoting energy dissipation, reducing turbulence intensity, and accelerating slurry sedimentation. This feature contributes to higher throughput and improved thickening efficiency.

3.5 Automatic Rake Lifting and Overload Protection

A torque-sensing control system enables automatic rake lifting during overload conditions, preventing rake burial and mechanical damage. This protection mechanism ensures safe, stable, and long-term operation.

3.6 Dual Overflow Weir Design

The rational feedwell configuration creates a dual overflow weir effect, improving overflow hydraulics and producing clearer reclaimed water suitable for reuse in the process plant.

4. Main Components of the Thickener

1. Bridge

2. Drive Unit

3. Fixed Cylinder

4. Feed Distribution Cone

5. Slurry Feed Pipeline

6. Flocculant Dosing System

7. Degassing Cylinder

8. Rake Assembly

9. Drive Shaft

10. Electrical Control System

11. Hydraulic Power Unit

5. Applications and Industries Served

This mineral processing thickener is widely used for the concentration and clarification of slurries containing intermediate products, concentrates, and tailings in both metallic and non-metallic mining operations. Typical applications include:

l Mining and mineral processing plants

l Tailings thickening and water recovery systems

l Metallurgical processing circuits

l Industrial solid–liquid separation projects

The equipment provides stable operating conditions for downstream filtration, water recycling, and tailings management, supporting sustainable and efficient plant operation.

6. Technical Advantages Summary

l High-efficiency solid–liquid separation

l Advanced hydraulic drive thickener

l Reliable mining thickener for tailings and concentrates

l High underflow density and clear overflow water

l Low maintenance, long service life

l Suitable for large-scale, continuous mining operations