Overview

The NZY Hydraulic Central Drive Deep Cone Thickener is a high-efficiency thickening and clarification system designed for the concentration and solid–liquid separation of high-solids slurries. It is widely used in metallic and non-metallic mineral processing, as well as in coal preparation, chemical, metallurgical, and environmental protection industries.

This thickener is suitable for intermediate products, concentrates, and tailings, as well as for industrial wastewater and process water recovery systems.

By combining a deep cone tank structure with a low-speed, high-torque hydraulic central drive, the NZY thickener delivers superior underflow density, improved clarification efficiency, and stable long-term operation compared with conventional shallow or peripheral-drive thickeners.

1. Thickener Equipment Overview (Mining & Mineral Processing Applications)

A thickener is a critical large-scale process equipment widely used for solid–liquid separation and slurry concentration in mining, mineral processing, metallurgy, chemical processing, and environmental engineering. Its core function is to accelerate the settling of solid particles through gravity sedimentation combined with flocculation, while producing clarified overflow water suitable for reuse or controlled discharge.

In mineral processing plants and tailings treatment systems, thickeners are typically installed downstream of grinding, flotation, gravity separation, and classification circuits. They are used for the concentration of intermediate products, mineral concentrates, and tailings slurry, providing stable feed conditions for filtration, slurry transport, water recovery, and tailings disposal.

With increasingly fine ore particle sizes, higher plant throughput requirements, and stricter water-recycling standards, modern mining thickeners have evolved into heavy-duty, high-efficiency process units that integrate:

l Advanced flocculation technology

l Stable and reliable drive systems

l Intelligent control and protection

l Optimized tank hydraulics

These developments significantly improve thickening efficiency, operational stability, and water recovery performance.

1. Model Designation

N – Thickener

Z – Deep Cone / Deep Tank Structure

Y – Hydraulic Drive

■ – Thickener Tank Inner Diameter (m)

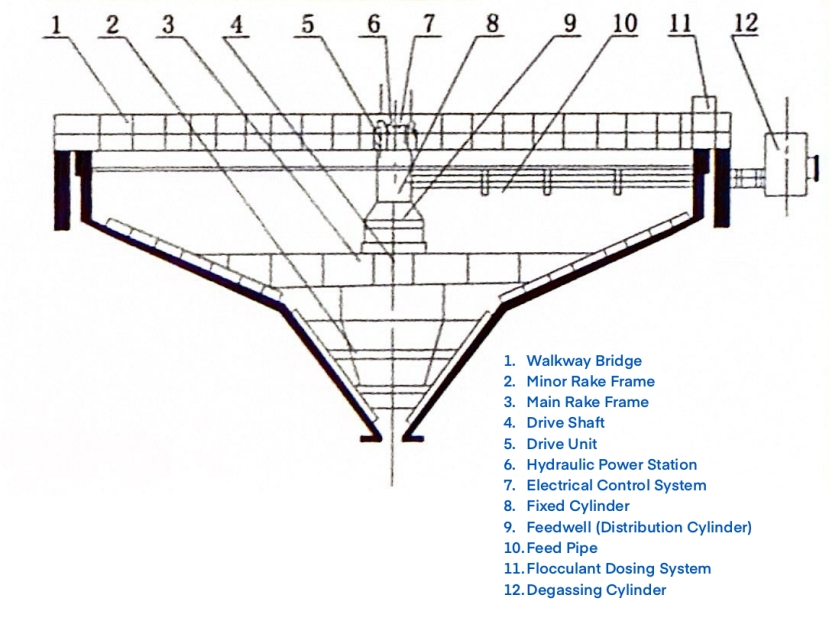

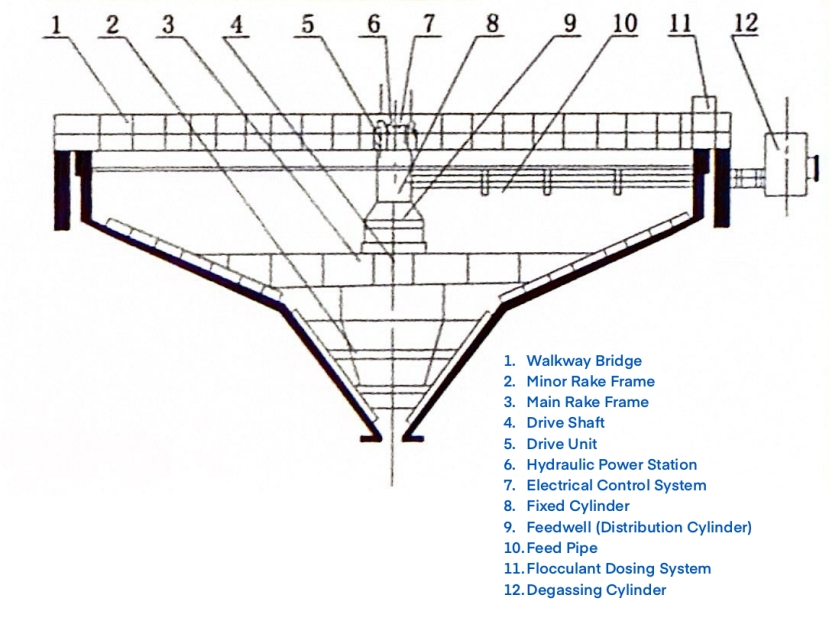

2. Structure and Working Principle

The NZY thickener features a vertical deep cylindrical tank with a conical bottom. Slurry is evenly introduced through the central feed well, where optimized mixing and flocculation promote rapid particle aggregation.

l Coarse and flocculated solids settle quickly under gravity, forming a high-density compression zone in the deep cone section

l Clarified overflow water is discharged from the top launder, suitable for reuse in the process circuit

l Concentrated underflow solids are continuously raked toward the cone bottom and discharged in a stable and controlled manner

l The hydraulic central drive system provides smooth torque transmission and automatic protection under high-load or abnormal conditions

3. Main Technical Features

Deep Cone Tank Design

l Increased effective settling height and compression zone

l Significantly higher underflow concentration and thickening efficiency

Optimized Flocculation and Raking System

l Scientifically designed feed well and mixing conditions

l Enhanced floc growth, faster settling rate, and improved overflow clarity

Hydraulic Central Drive System

l Low-speed, high-torque operation suitable for high-density slurries

l Equipped with overload protection, automatic rake lifting, and torque monitoring

Large Capacity with Compact Footprint

l Smaller installation area compared with conventional thickeners

l High unit-area throughput, ideal for large-scale plants and retrofit projects

High Automation and Low Maintenance

l Easily integrated with PLC / DCS control systems

l Reduced mechanical wear, fewer failure points, and lower operating costs

4. Typical Applications

l Thickening of concentrates, middlings, and tailings in mineral processing plants

l Coal slurry concentration in coal preparation facilities

l Slurry clarification and solid–liquid separation in chemical processes

l Sludge thickening and industrial wastewater treatment in environmental projects

l Water recovery systems in metallurgical and mining operations