1. Thickener Equipment Overview (Mining & Mineral Processing Applications)

A thickener is a critical large-scale process equipment widely used for solid–liquid separation and slurry concentration in mining, mineral processing, metallurgy, chemical processing, and environmental engineering. Its core function is to accelerate the settling of solid particles through gravity sedimentation combined with flocculation, while producing clarified overflow water suitable for reuse or controlled discharge.

In mineral processing plants and tailings treatment systems, thickeners are typically installed downstream of grinding, flotation, gravity separation, and classification circuits. They are used for the concentration of intermediate products, mineral concentrates, and tailings slurry, providing stable feed conditions for filtration, slurry transport, water recovery, and tailings disposal.

With increasingly fine ore particle sizes, higher plant throughput requirements, and stricter water-recycling standards, modern mining thickeners have evolved into heavy-duty, high-efficiency process units that integrate:

l Advanced flocculation technology

l Stable and reliable drive systems

l Intelligent control and protection

l Optimized tank hydraulics

These developments significantly improve thickening efficiency, operational stability, and water recovery performance.

2. Key Features

l The rake mechanism adopts a covered truss structure, providing high structural rigidity and long-term operational stability.

l The drive system typically uses a direct-coupled motor with cycloidal pinwheel reducer or cylindrical worm gear reducer, resulting in a compact, rational layout.

l High transmission efficiency, large handling capacity, and stable torque output.

l Easy installation and maintenance, with convenient access for inspection and servicing.

l Designed for continuous, reliable thickening operations under heavy-duty industrial conditions.

3. Main Applications

The NC/T Series Peripheral Drive Thickener is primarily used for the thickening of concentrates and tailings in:

l Ferrous metal beneficiation plants

l Non-ferrous metal mineral processing

l Coal preparation plants

l Other industries requiring solid–liquid separation and slurry concentration

It is suitable for both concentrate thickening and tailings dewatering, ensuring stable underflow concentration and clarified overflow.

4. Model Designation

l N — Thickener

l C — Peripheral roller drive

l T — Peripheral roller drive

l ■ — Thickening tank internal diameter (m)

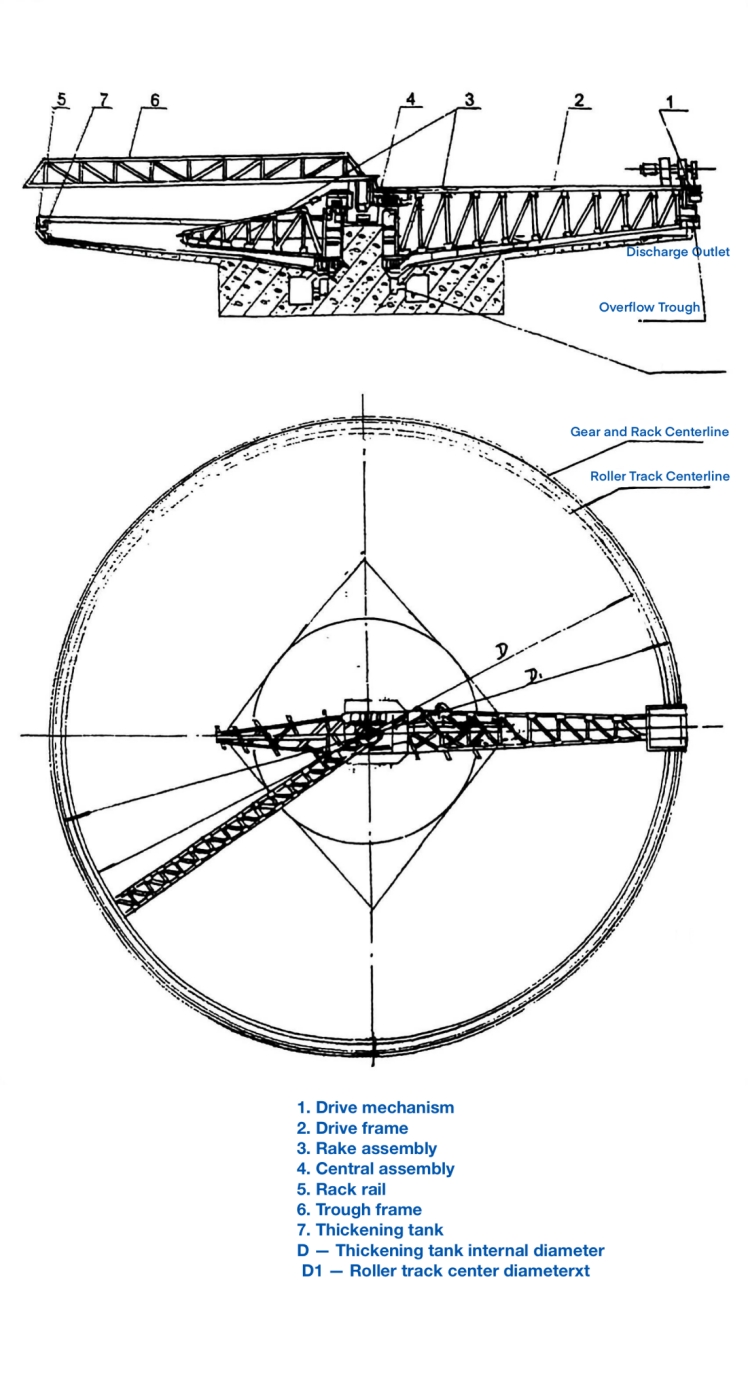

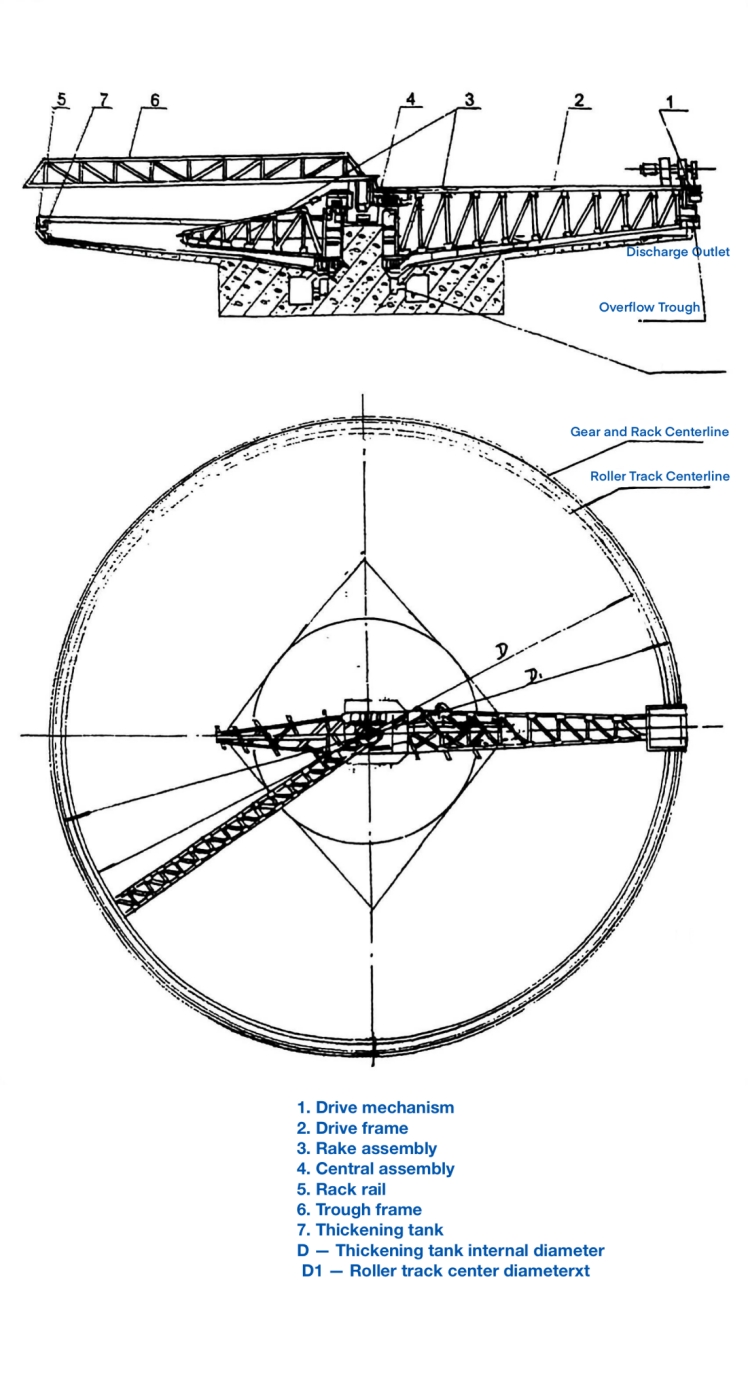

5. Peripheral Drive Thickener – Main Components

1. Drive mechanism

2. Drive frame

3. Rake assembly

4. Central assembly

5. Rack rail

6. Trough frame

7. Thickening tank

D — Thickening tank internal diameter

D1 — Roller track center diameter