A Technical Comparison of Dewatering Technologies for Mining and Mineral Processing

Overview of Filtration Technology Selection in Mining

In mining and mineral processing operations, slurry dewatering and tailings management play a critical role in water recovery, downstream material handling, and overall plant efficiency. Filtration technology selection should therefore be guided by process requirements, operational stability, and total lifecycle cost, rather than by reported cake moisture alone.

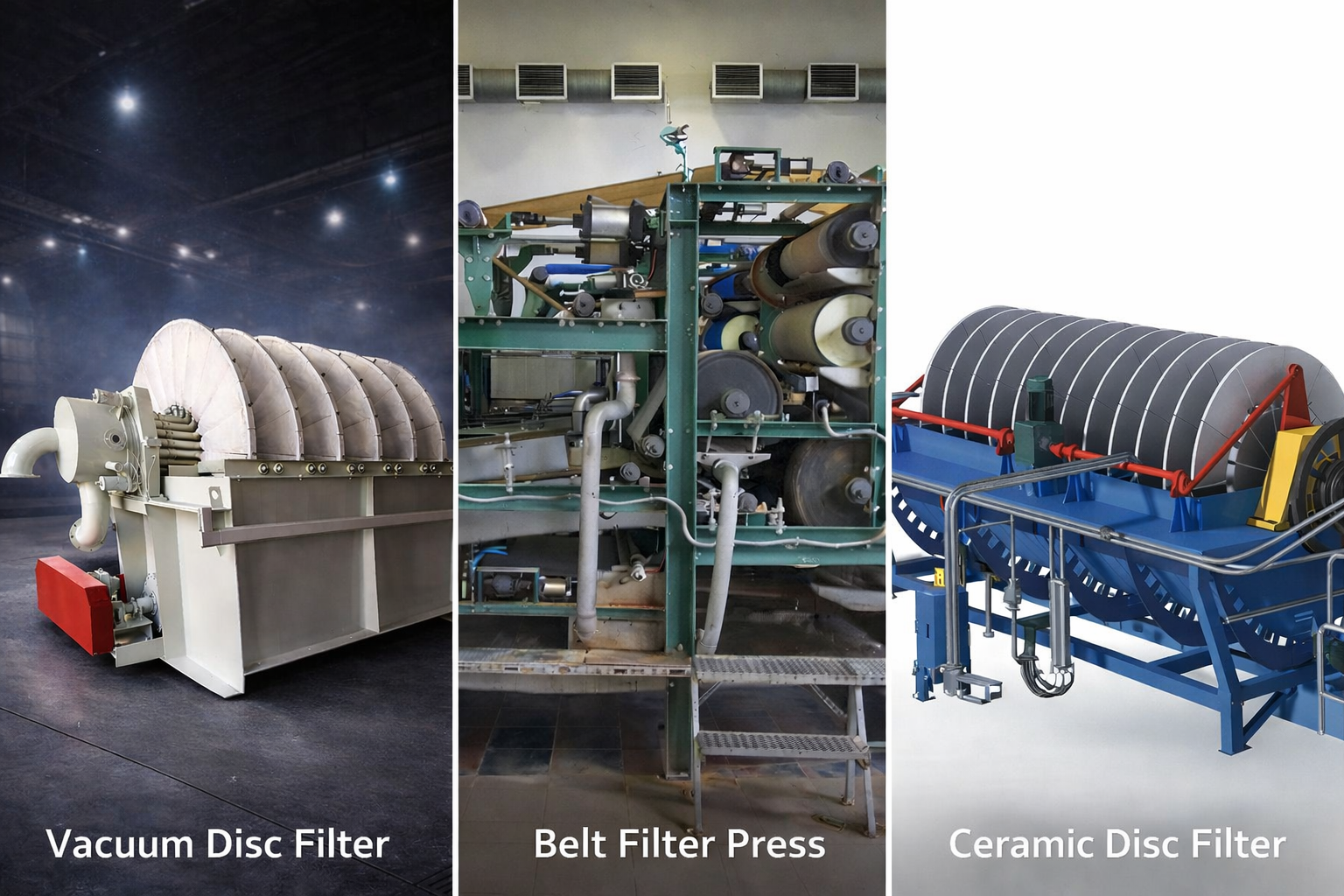

Among continuous filtration systems, vacuum-based dewatering technologies remain widely applied due to their operational reliability and suitability for large throughputs. This article presents a technical comparison of three commonly implemented dewatering technologies used in mining and mineral processing:

Synthetic-cloth vacuum disc filters

Vacuum belt filters

Ceramic disc filters

The comparison is based on fundamental filtration principles, operational considerations, and published industry research, with the objective of supporting informed and application-appropriate equipment selection.

Separation Mechanisms and Operating Limitations

Synthetic-Cloth Vacuum Disc Filters

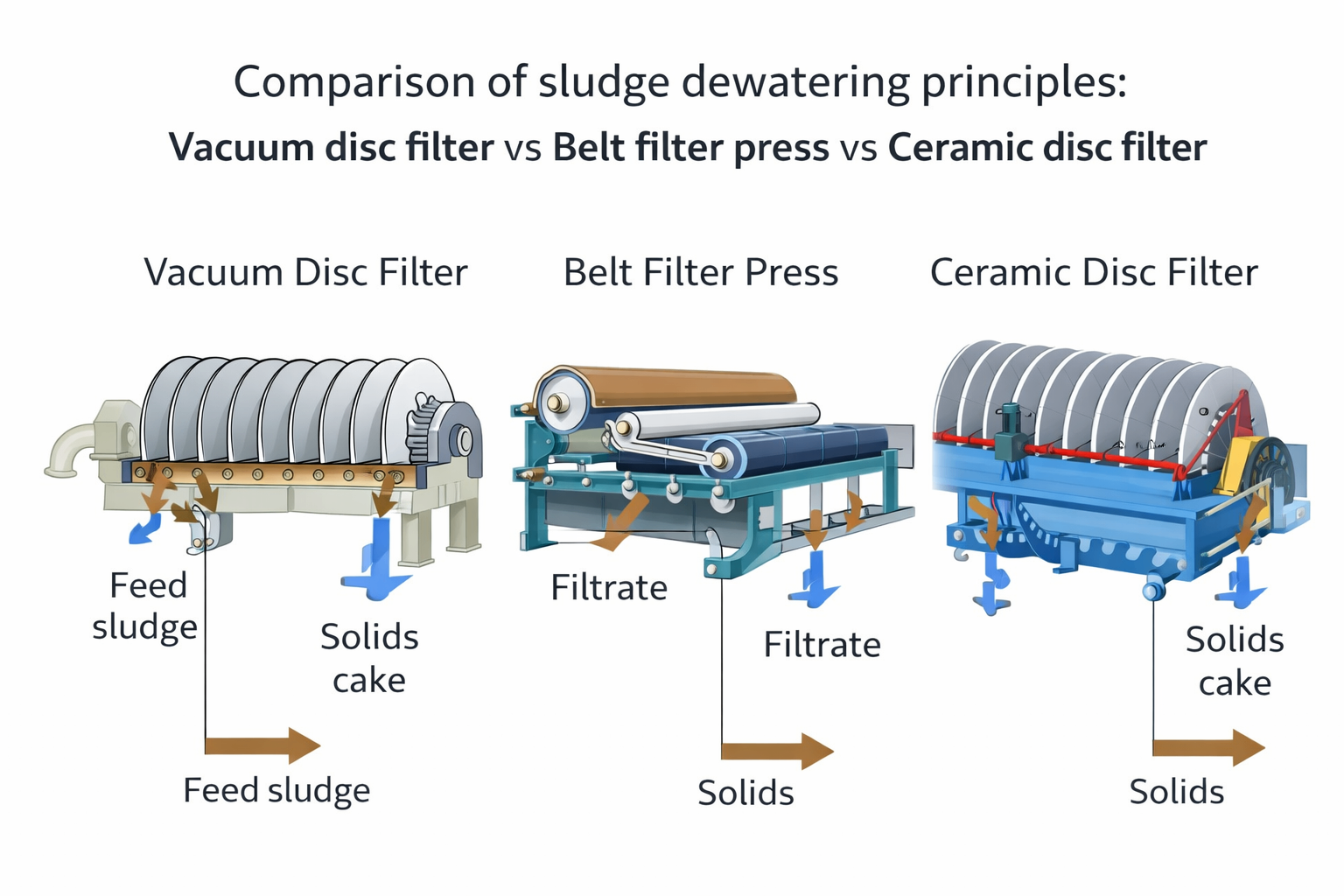

Synthetic-cloth vacuum disc filters operate as continuous rotary vacuum filtration systems. Slurry is introduced into a filter trough, where cake formation occurs on individual disc sectors as they rotate through the slurry zone. Subsequent drainage and drying zones enable liquid removal prior to cake discharge.

As with all vacuum filtration equipment, the achievable pressure differential is inherently limited, typically remaining below 1 bar. This constraint on final cake dryness is a characteristic of the vacuum filtration process itself rather than of any specific equipment design.

Within these operating limits, modern vacuum disc filters have benefited from ongoing improvements in cloth materials, sector design, and cleaning systems, resulting in enhanced operational stability and predictable performance across a wide range of mining slurry applications. Their compact footprint, modular construction, and continuous operation make synthetic-cloth disc filters a well-established solution for concentrate and tailings dewatering where balanced throughput and maintainability are required.

Vacuum Belt Filters

Vacuum belt filters apply the same vacuum filtration principle but utilize a horizontal moving belt as the filtration surface. This configuration allows for extended residence time and facilitates the incorporation of multi-stage cake washing, which can be advantageous when washing efficiency or soluble removal is a primary process requirement.

Belt filters provide good visual accessibility and operational flexibility; however, they generally require larger installation footprints and involve more mechanically complex systems compared to rotary disc filters. Their selection is therefore closely linked to plant layout constraints and specific washing objectives rather than dewatering performance alone.

Ceramic Disc Filters

Ceramic disc filters employ micro-porous ceramic filter sectors, where liquid retention is achieved through capillary action as air is drawn through the porous structure. Under suitable feed conditions, ceramic filtration can achieve low cake moisture levels.

This performance, however, is associated with higher capital cost and requires continuous management of ceramic-sector cleaning, regeneration, and replacement throughout the equipment lifecycle. Feed chemistry, slurry composition, and operational discipline must be compatible with ceramic filtration technology to ensure long-term reliability and economic viability.

Performance Findings from Published Comparative Studies

Meaningful comparisons of dewatering technologies should normalize performance by specific solids throughput (kg/m²·h), required filter area, and unit count, rather than relying on moisture content as a standalone indicator.

A widely referenced comparative study presented at Mine Fill 2014 evaluated disc filters, belt filters, and pressure filtration for representative mining applications. The study demonstrated that equipment selection is primarily driven by process objectives, layout constraints, and operational practices, rather than by any single performance metric.

Published data and accumulated industry experience support several consistent conclusions:

Synthetic-cloth vacuum disc filters and vacuum belt filters are both proven continuous dewatering solutions, with selection depending on washing requirements, footprint limitations, and mechanical complexity.

Vacuum filtration performance should be assessed within realistic pressure-differential limits, rather than based on idealized dryness claims.

Ceramic disc filtration can deliver excellent results when feed conditions and maintenance practices are well aligned with the technology’s operating parameters.

Filtration Media Selection and Maintainability

In cloth-based filtration systems, the filtration medium is a primary performance variable, not a secondary consumable. Fiber type, weave structure, permeability, and cleaning characteristics directly influence cake formation, airflow resistance, blinding tendency, and operating stability.

In practice:

Synthetic-cloth vacuum disc filters offer a compact footprint, modular sector maintenance, and predictable consumable management when cloth specifications and cleaning protocols are clearly defined.

Vacuum belt filters provide flexibility for cake washing and improved visual access, which may be advantageous in specific plant configurations.

Ceramic disc filters eliminate cloth handling but introduce ceramic-sector lifecycle considerations that must be explicitly included in economic evaluations.

Practical Guidance for Dewatering Technology Selection

From an engineering perspective, filtration technology selection should be based on measured slurry properties, test work, and comprehensive lifecycle cost analysis, rather than on isolated performance indicators.

In general:

Select synthetic-cloth vacuum disc filtration when a compact, continuous dewatering solution with balanced throughput, operational stability, and maintainability is required.

Select vacuum belt filtration when extended residence time or washing efficiency is a dominant process requirement.

Select ceramic disc filtration when feed conditions are well suited and long-term operating discipline supports ceramic-sector maintenance.

A structured, data-driven selection methodology remains the most reliable approach to avoid costly misapplication of otherwise proven filtration technologies.

References

Hahn, J., Simms, P., and Thompson, P. Comparison of Tailings Dewatering Technologies for Mine Backfill Applications. Proceedings of Mine Fill 2014, Australian Centre for Geomechanics (ACG), Perth, Australia.

Tarleton, E. S. Solid/Liquid Separation Equipment Selection and Process Design. FILTECH Conference Proceedings.

Bokela GmbH. Theory and Practice of Filtration in the Alumina Industry. Technical industry publication.

van Deventer, J. S. J. et al. An Assessment of Ceramic Filtration for Metallurgical Applications. MSc Dissertation, University of the Witwatersrand.

Le Roux, J. D. et al. Optimal Ceramic Filtration Operating Conditions for Iron Ore Concentrates. Minerals Engineering, Elsevier, 2018.

ScienceDirect Topics – Filter Cloth: Properties, Weave, and Filtration Performance. Elsevier.